About Us

Vatsal Exports LLP was founded with the goal of exporting textile products of superior quality. We are a comprehensive solution provider for your textile requirements that includes proffering knitted fabrics, garments and 100% cotton yarn with modern facilities.

With our manufacturing facilities, textile companies can discover best prices and people, as well as market trends and trade the highest quality materials. In terms of both quality and infrastructure, our spinning facilities are among the best in Gujarat, India.

Vatsal Exports LLP strives to become one of the best exporters of Raw Cotton, Cotton Yarn, Knitted Fabrics and Garments across the globe. We offer a quality assurance program after sales that makes us reliable and approachable textile partners. We are able to add value to our service by sourcing weaving fabrics and home textiles products, thus establishing long-term professional relationships with our buyers.

We keep our fundamentals intact while always staying relevant with the dynamic nature of the textile industry. The textile design researchers and engineers at our company work closely with cotton to design and develop high-quality products.

We offer our clients a reliable, approachable service that includes designing, fabric sourcing, importing, printing, and packaging while staying relevant to the textile industry’s rapid development.

Production Capacity

Our manufacturing units possess a facility with 27360 spindles installed and a capacity to produce 23 metric tons per day. Forward integration has included the installation of an ultra-modern Fabric Manufacturing, Dyeing & Processing Unit with soft flow and continuous dyeing with a capacity of 28 metric tons per day and a Rotary Printing Unit, as well as a Garment Facility with the latest stitching technology capable of producing 28000 pieces per day.

Our organization has established one of the most advanced plants in the textile industry. We have done this by offering state-of-the-art technology, which has been cold-spun by our research team to develop an innovative solution that is revolutionizing the industry.

We plan to increase our production capacity to 54320 spindles by April 2024 in response to the increased customer demand.

Our Vision

Aiming to become the global leader in the textile industry & provide sumptuous & eco-friendly textiles along with innovative ideas and quality. Being one of the leading names in the textile industry, your needs are our top priority. Whether it’s quality or price, or something completely different, we find you the perfect textile material. Our team will find the right fit that will make your business a success.

Our Mission

We strive to provide first-class customer service, innovative design, and search functionality to ensure a delightful buyer experience. Our company has been working endlessly on creating a product that can transform the lives of millions. Furthermore, we are striving to create a brand that represents strength and sophistication. Through creative solutions, we seek to meet our clients’ needs and ensure the highest quality of work.

Our Values

Integrity

Proficiency

Teamwork

Client success

Innovation

Respect

Efficiency

Trust

Our Processes

01 - Cotton Farming

Cotton is the world’s most widely produced natural fiber. It is a product of the seed pod of the cotton plant, which grows in hotter regions around the world. It can be tightly woven, printed, dyed and treated to produce cloth in a wide variety of textures, colors and patterns. Cotton is a natural fiber grown on a plant related to the commonly-found garden species hibiscus. Cotton seeds are planted in spring and grow into the plant later which briefly grows pink- and cream-colored flowers that, once pollinated, drop off and are replaced with fruit, better known as cotton bolls. Inside the cotton ball is fluffy, white lint as well as cotton seeds. Once the plant has been defoliated, and the bolls have cracked open to reveal the lint, the cotton is ready to be picked.

02 - Ginning

Our machines have been designed and built to handle material with a high degree of abrasivity. The cotton with seeds in their balls is plucked from the field. Then it is made to pass through the gin. The process starts by measuring the moisture of the cotton; this helps determine how much heat will be applied to open the fiber.

Cleaning is done in two stages. First, the cotton is mixed with air to remove impurities and send them to a waste pile. Then another cleaning takes place where seed cotton is removed from lint by sawblades. In the gin stand, full of whirring machines and buzzing valves, the last bits of lint are cleaned and removed. The ginning process ensures clean cotton, which is then pressed into 500-pound bales called “bales”. Each bale is wrapped with a band containing information on its characteristics like color and length of the fiber. It then goes to the market.

03 - Spinning

Spinning is a procedure of producing/converting fiber materials in yarns. On an initial stage it goes through the blow room where the size of cotton becomes smaller by the help of machinery followed by carding. After carding, the process is continued by drawing which includes attenuating in spinning mills. The silver produced by drawing is then processed for combining where consistent size of yarn is attained. It is then stepped further to roving for the purpose to prepare the input package. This roving is attenuated by rollers and then spun around the rotating spindle.

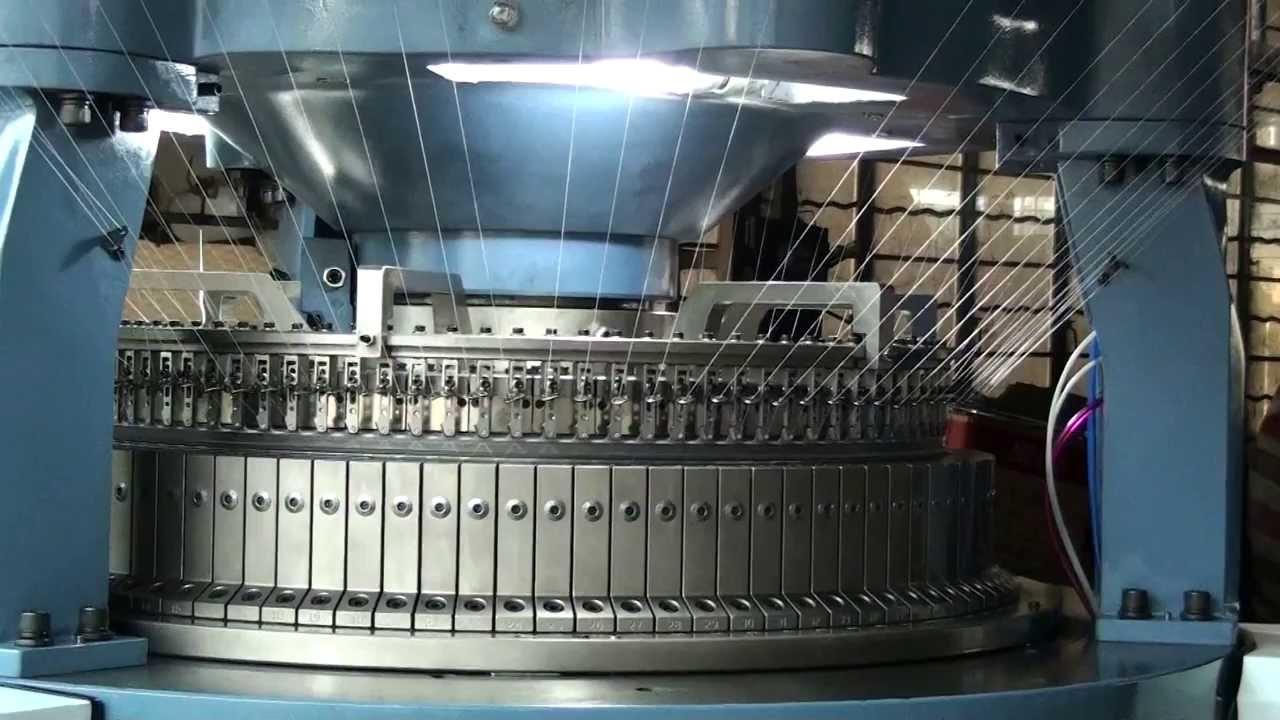

04 - Knitting

The knitting section is equipped with top of the-line machinery Mayer and Cie of Germany, the machines are equipped with special attachments to produce Lycra fabrics. A well-integrated system of stringer quality measures checks all fabrics meticulously to eliminate contamination and other faults. We always believe that yarn is the core material for fabrics.

05 - Dyeing

A dyeing process is the interaction between a dye and a fiber, as well as the movement of dye into the internal part of the fiber. Generally, a dyeing process involves adsorption (transfer of dyes from the aqueous solution onto the fiber surface) and diffusion (dyes diffused into the fiber).

06 - Printing

The four main methods of textile printing are block, roller, screen, and heat transfer printing. In each of these methods, the application of the color, usually as a thickened paste, is followed by fixation, usually curing, and then removal of excess color by washing.

07 - Garment

Our Reach

With its global appeal and international clientele, Vatsal Exports LLP serves customers worldwide. Through the export of our goods to more than 10 countries, we have established a reputation for quality and class. Globally, we provide the most refined and premium quality product sourced from Gujarat, India.

Client Reviews

It's been great working with the 'Vatsal Exports LLP' team . We have always found them truly available for any service at any point of time. We would like to appreciate the work culture that these guys follow. The rates quoted are realistic and pretty much competitive. The edge over other textile suppliers and 'Vatsal Export' is the fulfilment of commitment irrespective of ups and downs of the market. Our wishes are with them for future prospects and hoping to work for a long term period with such a young and dynamic company

We are delighted to have a young, tech-savvy textile partner like 'Vatsal Exports'. They are always on at fulfilling their customers' demands and queries because they have a strong and 24*7 responsive workforce. Always eager to take on new projects and experiment with new products for their clients. Order follow-up and weekly updates help us stay on top of the fabric market. Fabric prices are excellent, and delivery is prompt. Mr. Vatsal (the founder) has become a dear friend who has worked tirelessly to bring about this change in the textile industry. We wish them the best of luck in their future endeavours. They have our back.

Vatsal Exports LLP" has made my job much easier. I didn't have to go to a lot of places to find my products. They made it simple for me to obtain my product. Their team is extremely pleasant, cooperative, and hardworking. They do possess proven ability and extraordinary customer support. I'd be delighted to inform and recommend others about "Vatsal Exports LLP" as Gujarat's fastest growing textile exporters for quality products.

“Consuming Less, Creating More”

At Vatsal Exports LLP, we strive to meet annual sustainability goals every year in these three important areas:

- Fibers sourced ethically: Products under our brands will be made with at least 80% cotton sourced sustainably and 50% recycled polyester.

- Decreased water consumption: Our manufacturing operations will use 25% less water per unit of production.

- Depreciating greenhouse gasses: We plan to reduce greenhouse gas emissions by 2.5% per year.

“The Eight Sustainability Threads”

Their products are phenomenal, and they provide excellent customer service. When compared to the market or malls, you will get the best deal and product. I really liked their yarn, the quality, and the softness, and I am pleased with the products and the hassle free services they provide.